Back to Frequently asked questions

Courtesy of Peter Claassen

In creating the ultimate driving experience, those clever BMW

engineers decided on a shift system with lots of rubber isolation

and relatively long throws. The ultimate shifting works great

when the car rolls off the dealers lot, but as the odometer

climbs in the 100's of thousands of miles, the rubber gets soft

and the shifts become looser and vaguer. Maybe you are desiring a

quicker shift pattern for the stoplight Grand Prix. A quick shift

replacement is as simple as changing the fulcrum point on the

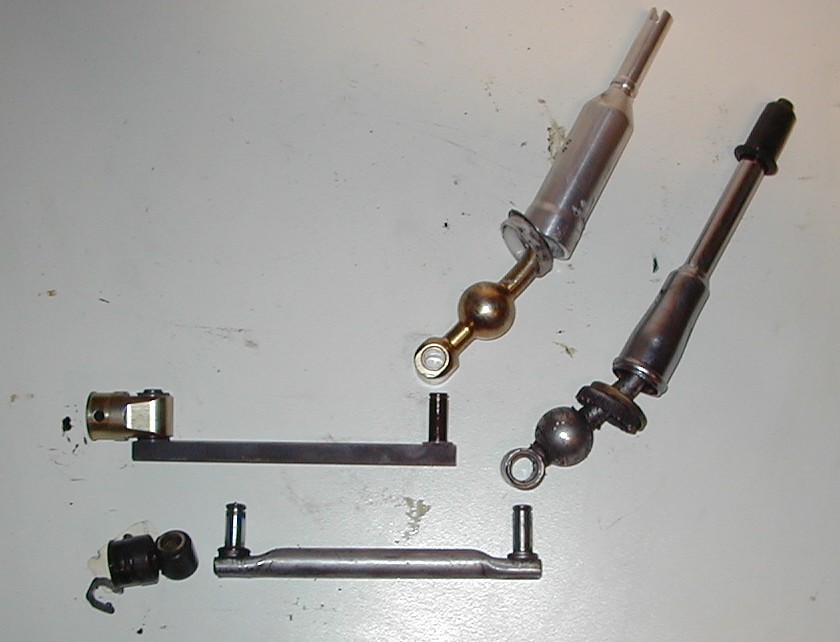

shift lever. See the Photo 1 comparing a stock shifter (bottom of

photo) with an after market shifter. As you can see the distance

from the bottom of the ball to the bottom link is further than

stock. This decreases the distance the knob has to travel to move

from 1st to 2nd gear for instance. You get a tighter shift

pattern, shorter throws, especially way out in right field to 5th

gear, and less interference with your power adapter in the

cigarette lighter. IMHO opinion there is a trade off, after all

those Munich Engineers are not dumb!, the factory shift takes

less effort and tends to be less "notchie". The short

shifters take a little more "oomph" and seem to be more

"notchie" especially on higher mileage transmissions.

Mine is especially vague for shifting into 1st or reverse from

neutral. But what the heck!, short shifters are a nice addition

to an E 12.

You have several options in short shifters. The first and least

expensive is to use a shifter from any 2002, the bottom throw

distance is similar to the after market units. (see Photo 2, 2002

shifter is on the left) Prices range from free to $40 bucks.

There are several fitment issues related to the 5 speeds (vs 4

speeds) that we will cover. The second is to get a M3 shifter new

from BMW, approx. $75. The third is to go to UUC, Metric

Mechanic, or Auto Solutions (An Auto Solutions shifter is shown

in photos 1). You need to check current prices but they tend to

range around $200. For that you get a complete linkage, bushings,

and clips. Look at Photo 1 and Photo ? to see the Auto Solutions

unit. It is way more stout, robust, and manly than the factory

unit making it ideal for racing and extreme use. Auto Solutions

is extremely helpful over the phone with technical support.

While you are changing your shifter it is a great opportunity to

replace that worn out soft and cracked rubber. The rubber

affecting shifting occurs in 3 different locations. First, there

are 2 aluminum and rubber isolators that fasten to the rear end

of the tranny. Approx. $15 each. Second there is a rubber keeper

at the tail end of the (5 speed only) sheet metal shift deck. You

can replace it with OEM from a dealer. We advocate superseding

this rubber with a more positive attachment (See photo 2, the

black rubber isolator with nuts on each end). Third, replace the

transmission rubber mount near the exhaust hanger. Approx. $15.

Better yet, get a tranny crossbar from an E28 and install 2 new

tranny mounts. (The Gertrage 265 has provision for a second

mount)

The good news is that you can change the shifter with out

removing the transmission. It will require working under the car.

Some operations will have to be done by Braille since the rubber

guibo is in the way of seeing the shift linkage attachments.

Disassembly:

Leave the tranny in 4th gear or neutral. Once apart you will not

be able to shift the car.

In the car. Remove shift knob. (81 and earlier have threaded

knobs). Remove the side trim screws holding the leatherette flat

panel which holds the shift boot. Slip off of shift rod. Remove

black rubber booty from shift rod. The shifter resides in a

circular assembly integral to the black metal deck. At the inner

periphery is a "c" clip with 2 little holes at the

ends. This clip needs to be compressed enough to pop out of the

black circle. Use your handy BMW circlip tool, or 2 drywall

screws in the 2 holes to squeeze ring, or 2 small screwdrivers

approx. 3/8" away from little holes to lever the circlip.

(There are indentations at those places allowing a screwdriver to

slip into place.)

Underneath the car. Remove the circlip holding the transfer link

to the shift rod bottom connector. Keep track of the washers and

spacers that come off. You will have to wiggle the shifter apart

from the transfer rod pin. Voila ! The shifter will pop out from

the top.

Assembly is the opposite.

Removing Shift Linkage

This is where the braille part begins. The transfer linkage

connects with a pin and female connector to a "cup"

fastener that is pinned to a ½" diameter rod at the rear of

the transmission. The rod is cross drilled for the pin. A 1"

diameter x 3/16" wide x very thin spring steel "C"

keeper slides over the cup connector to keep the pin from falling

out. This entire assembly is directly above and in front of the

guibo. (Rubber donut) Your mission is to slide the spring clip

towards the rear of the car so that you can push out the pin.

Stout fingernails or a small screwdriver are helpful in this

endeavor. Study the photos. There are shoulders that keep the

spring steel keeper in the correct position. You have to slide it

over those shoulders. Optionally, you can slide it forward as

well. The reason for 4th gear is that it makes it easier to

access the pin. Once the pin falls on the floor, the linkage will

pull out. Note the orientation of the pin hole at the rear of the

tranny rod.

Rebuilding the shift linkage:

The shift and the connector cup come with factory nylon bushings

which are probably worn out and ovoid in shape. You have 4

options for replacement: 1) Get new BMW nylon bushings from your

friendly dealer. 2) Buy new bronze bushings from BMP. Aprrox.

$35. (There is a catch 22, see below) Shown in Photos. 3) If you

bought a replacement short shift, it should come all set with new

everything. 4) El cheapo. I found 3/8" x 1" bronze

bushings at the local hardware store for $2.50 each. (Buy extras)

The need to be reamed out to the 10.5 mm diameter of the pins and

cut to the correct length. E Mail me for reaming instructions.

The bronze bushings do not fit as tightly into the housings as

the nylon units do which might cause some wear on the housings in

the course of 200,000 miles or so.

Butter the pins w/ 90 lb grease. Put the cup connector and

transfer rod back together using spacer washers and a new

"C" clip on the pin. The rear pin goes together when

re-installing the shift lever. Pre-fit the spring clip on the cup

shoulders leaving the pin hole open. Put back on the rear of the

tranny rod. By braille, re-insert the metal pin. (Put grease on

it to make it sticky) Slide the spring clip into its correct

position and go get a beer.

4 Speeds, 5 Speeds and Catch 22's…………….

Somewhere I read that the 4 speed linkage pieces are similar if

not identical to the 2002. Most critical is that the transfer

linkage pins are 10 mm diameter. Secondly the transfer linkage is

longer. Thirdly, the black metal deck has no rear stabilization /

connector. The 5 speeds have a 10.5 mm pins on the transfer

linkage. Thus the 2002 shifter bushings will not work with the 5

speed linkage. However the bushing outside diameters appear to be

the same. Catch 22, BMP carries 10mm bronze bushings and may not

have the 10.5mm bushings. Unless you have an amazing metalworking

machine shop, the bronze bushings cannot be reamed out 0.5mm.

Hence, the el cheapo bronze bushing solution. In any case, you

need to have your bushings lined up in a row before you start

depending on a 4 speed or 5 speed application.

Dave Spencer adds:

"The original bushing is 13mm OD x 10.5mm ID x 17mm (plus

the flange). Four 1/2" OD x 3/8" ID x 1/2" bronze

bushings can be modified to work. Simply ream the inside to

10.5mm ID and cut the length to 8.5mm to the inside of the top

hat flange. I have noticed the flange varies in thickness

depending on where you get the bushings. If a 10.5mm drill bit

cannot be found, a "Z" index bit is very close (10.4mm

- I used one and used a dowel rod and some 220 sandpaper to get

the other 0.1mm). You can get a machine shop to do this for much

less than the $35 some mail order places charge for the set if

you don't have the correct drill bit".

Replacing Rubber Stuff

This step requires pulling the metal shift deck apart to replace

the rubber but should make for crisper shifting. The shifter deck

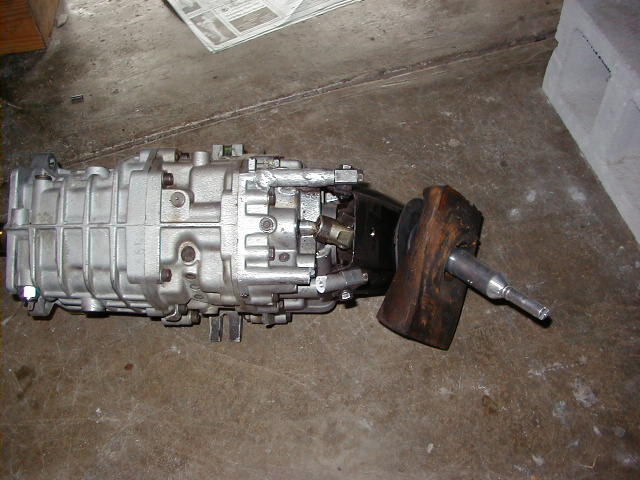

is stamped steel piece cantilevered off the rear of the tranny.

It is secured to the top of the tranny with 2 bolts via the

aluminum and rubber pieces.(isolators) …… (For 5 speeds

only), the rear of the deck is stabilized with a large rubber

nipple. To remove the deck, undo the 2 horizontal bolts from the

aluminum isolators. The black shift deck should slide down and

out away from the rear rubber nipple. If not there is a rusty nut

at the top of the hump that you have to un bolt. If you are

replacing the aluminum isolators, undo the 13mm bolts securing

them to the top of the tranny. Install new and rebolt. Do not

over torque, the castings are delicate. In fact these castings

are a crummy design on an otherwise great transmission.

Inspect the black sheet metal piece. Check the weld at the rear

"add on" tab. (5 speeds only). The short shift will add

more stress to all of the assemblies. (I know, my welds broke).

If you are a four speeder, you may adaptively install the

isolator to minimize unwanted shifting movements.

Reinstall the black metal deck. The horizontal bolts are fun to

get started since they are crowded by the side walls of the hump.

If you like, replace the rear rubber nipple with new from BMW, or

….

We recommend removing the factory brackets for the rear rubber

nipple assembly and replacing it with the more positive rubber

isolator. To do that swing the black metal piece up 1"

beneath the transmission hump. "Guesstimate" how far

rear of the sheet metal shift cut out that a hole should be

drilled. Drill hole down from inside the car. Bolt the isolator

into place. Sourcing the isolator is up to you. They are common

for electric motor mounts, small compressor mounts, etc. Some

sort of industrial supply must have them.

Replacing the transmission rubber mounts is pretty straight

forward. You will need to jack up the tranny while changing the

supports.

Auto Solutions shifter (top), OEM shifter (bottom), note difference in length below the balls. Note how beefy the A-S shifter is also note A-S bronze bushing.

Clockwise from top left: 2002 shifter, OEM shifter, black metal shift deck, black rubber isolator, BMP bushings and clip, cup connector w/ nylon bushing, keeper pin, spring metal circlip, 5 speed transfer linkage, BMP bronze bushings, large diameter retainer circlip not shown. Use far left hole on metal deck for rubber isolator.

BMP bronze bushing (half) 10mm, 3/8 x 1 bronze bushing prior to reaming and shortening, "c" clip

OEM connector cup (top), Auto Solutions (bottom), note indentations for spring circlip

Cup connector and circlip attached to tranny.

Note: Author bought a used tranny with broken mounting casting.

Had it welded. Other casting broke after a year of stress. Had it

welded. Drilled holes deep into tranny casing and tapped them for

40mm M6 bolts. No problems since.

Shows aluminum & rubber isolator connectors bolted to tranny castings and horizontally into the black metal shift deck.

Back to Frequently asked questions

© 2002, FirstFives.org™